A prototype essentially is used for the purpose of understanding the practical nature of the project prior it’s starting. It would not be wrong to say that enhancement of a project cannot be done once it is made practically. However, there is a scope of changing the set design prior to its construction or establishment. The changes can be made in the selection of themes, colors, figures, and other technicalities of the design.

The cnc machining services offer services all over the world. Yes, they charge at China prices. They do not hesitate in dealing with complications relating to the accuracy or repeated process. They believe in client satisfaction and quality services. The selection of alloys and metals, and have no concern irrespective to the size or batch of orders. They are efficient and fast in operations. Repeatable processes metals, alloys, and plastics. Computer Numeric Control (CNC) make use of computers in creating extremely small and precise cuts, different angles, as well as designs. The cuts and designs achieved using CNC exceed human capability producing machined parts at the absolute highest level of accuracy. Highly-talented engineers oversee the entire process for a flawless final product.

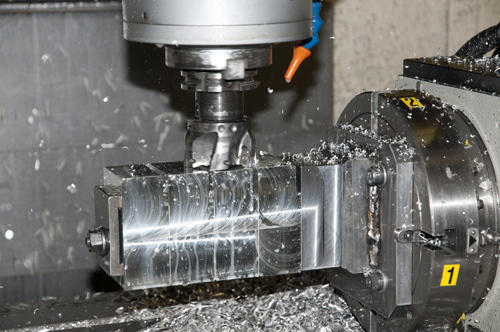

Some of the manufacturing processes also create varied designs by modifying or adding more materials and compiling them together, while on the other hand, the CNC process takes off the excess material and present the design in a more tractive and presentable manner. The reductive process is performed by using either the CNC Milling or the CNC Turning.

The CNC Milling process

To start the process, they take a rock hard raw material and cut it into pieces at different angles. The removal is done until the final product looks exactly like the design. It may be in form of a metal or an alloy. The waste collected is kept for further use in giving details to the project.

The CNC Turning process

It is an easy, fast and not so complex manufacturing process. It generally uses a lathe for striping the unwanted or excess material by making holes, cuts and finishes off with precision and accuracy. The result of the output you see is the outcome of the combined engineering talent put dedicatedly into the latest and advanced machinery. They believe in the use of updated and on-point technology for giving the best results out of nothing. The expectations are the latest stage of the practical and physical design. They surely work in an extreme environment to give a real yet unbelievable model of your imagination.

Usage of parts

The multiple Parts made using the CNC process have many uses, including the following. They are Automotive. They are used for Medical purposes. They are also beneficial in Consumer Electronics as well as Manufacturing of various products. The parts are widely used in Aviation and flying assistance. For many of us who are not aware, it is important to know that even the Aerospace use CNC processes parts. Also used in and for Computers, laptops, Robotics, and even more.