Microchannel heat exchangers represent a significant advancement in thermal management technology. These devices leverage a unique design that allows for enhanced heat transfer efficiency, making them suitable for a variety of applications across multiple industries.

Innovative Design and Functionality

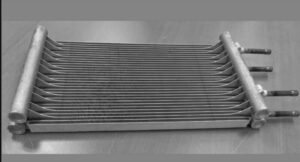

The core feature of microchannel heat exchangers is their structure, which consists of multiple small channels. This design facilitates high surface area interaction between the fluid and the exchanger surface, resulting in superior heat transfer capabilities. The compact nature of these exchangers also contributes to their lightweight and ease of integration into existing systems.

The manufacturing process for these devices typically involves techniques such as brazing and stamping, allowing for scalability and customization. This adaptability means that microchannel heat exchangers can be engineered to fit specific operational requirements, thus optimizing performance in diverse environments.

Applications Across Industries

HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, microchannel heat exchangers are increasingly employed due to their ability to reduce energy consumption while maintaining optimal performance. They are particularly effective in systems requiring efficient cooling, such as commercial refrigeration units. The high efficiency of these exchangers contributes to lower operational costs and reduced environmental impact.

Automotive Sector

The automotive industry has embraced microchannel technology, particularly in vehicle air conditioning systems and engine cooling. The lightweight design helps to decrease vehicle weight, which in turn enhances fuel efficiency. Moreover, the efficient heat transfer properties ensure rapid cooling, crucial for maintaining optimal engine performance.

Industrial Processes

In industrial applications, microchannel heat exchangers are used in processes that require precise temperature control. For instance, in chemical processing, these devices can facilitate effective heat management, promoting safety and efficiency. The robustness and reliability of microchannel technology make it an ideal choice for demanding environments.

Energy Generation

Microchannel heat exchangers are also making strides in the energy sector, specifically in power generation facilities. Their ability to efficiently manage the heat exchange process can lead to improved overall plant efficiency. As renewable energy technologies evolve, the versatility of these exchangers positions them as key components in future energy systems.

Performance and Efficiency

The performance of microchannel heat exchangers is often highlighted by their ability to handle high flow rates and pressure drops while maintaining low thermal resistance. This is crucial for applications that require rapid heat dissipation without compromising fluid dynamics.

Regular advancements in material science further enhance the performance of microchannel heat exchangers. For example, using corrosion-resistant materials increases longevity and reduces maintenance costs, making them an economically viable option in the long run.

Energy Savings and Environmental Impact

One of the most significant benefits of microchannel heat exchangers is their contribution to energy savings. By optimizing thermal performance, these devices help to lower energy consumption across various applications. This reduction not only translates to cost savings but also aligns with global efforts to decrease carbon emissions and promote sustainable practices. For more detailed insights into the technology, you can explore this microchannel heat exchanger resource.

Future Trends and Developments

Looking ahead, the future of microchannel heat exchangers appears promising, with ongoing research focused on enhancing their capabilities. Innovations such as the integration of smart technologies and advanced materials are expected to drive further improvements in efficiency and adaptability.

Moreover, as industries increasingly prioritize sustainability, microchannel heat exchangers will likely play a pivotal role in developing eco-friendly systems. Their ability to reduce energy consumption and improve heat management aligns with the growing demand for greener technologies.

A Result

The versatility of microchannel heat exchangers showcases their potential to revolutionize thermal management across various sectors. With their innovative design, superior performance, and adaptability, these devices are well-positioned to meet the evolving needs of modern applications. As industries continue to seek efficient and sustainable solutions, microchannel technology will undoubtedly remain at the forefront of thermal management advancements